Okulandelayo inqubo yokukhiqiza ephelele kusukela ku-SMT (ubuchwepheshe bokukhweza phezulu) kuya ku-DIP (iphakheji elikabili elikumugqa), kuya ekutholweni kwe-AI kanye ne-ASSY (umhlangano), kanye nabasebenzi bezobuchwepheshe abanikeza isiqondiso kuyo yonke inqubo. Le nqubo ihlanganisa izixhumanisi ezibalulekile ekukhiqizeni ngogesi ukuze kuqinisekiswe ukukhiqizwa kwekhwalithi ephezulu nokusebenza kahle.

Qedela inqubo yokukhiqiza kusuka ku-SMT→DIP→AI ukuhlola→ASSY

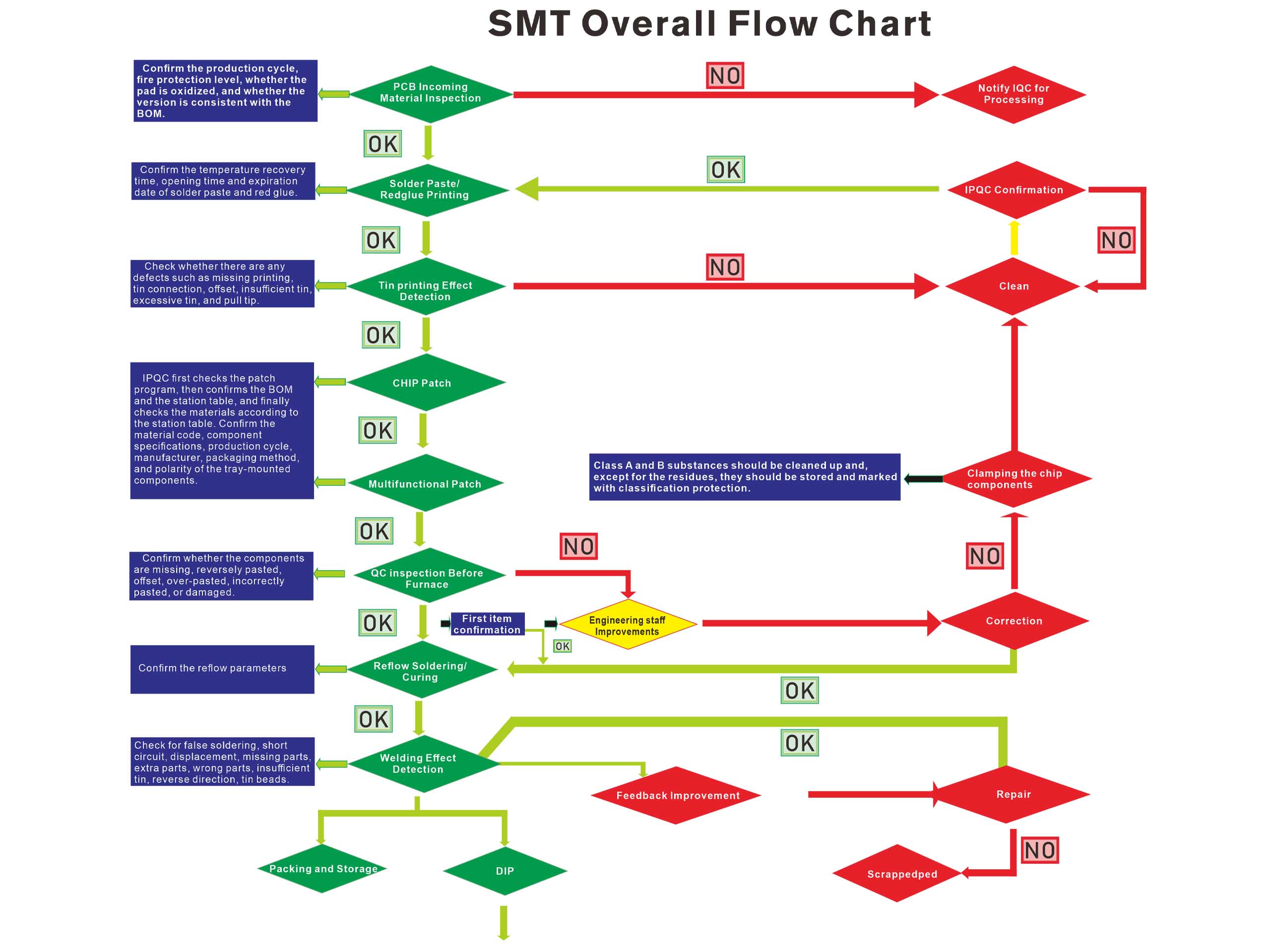

1. I-SMT (ubuchwepheshe bokukhweza phezulu)

I-SMT iyinqubo ewumnyombo yokukhiqiza i-elekthronikhi, esetshenziselwa kakhulu ukufaka izingxenye ze-surface mount (SMD) ku-PCB.

(1) Ukuphrinta kwe-solder paste

Izisetshenziswa: iphrinta yokunamathisela ye-solder.

Izinyathelo:

Lungisa i-PCB ebhentshini lokusebenza lephrinta.

Phrinta unamathisele we-solder ngokunembile kumaphedi e-PCB ngokusebenzisa insimbi yensimbi.

Hlola ikhwalithi yokuphrinta kwe-solder paste ukuze uqiniseke ukuthi ayikho i-offset, ukuphrinta engekho noma ukuphrinta ngokweqile.

Amaphuzu abalulekile:

I-viscosity nokuqina kwe-solder paste kufanele kuhlangabezane nezidingo.

Imeshi yensimbi idinga ukuhlanzwa njalo ukuze igweme ukuvaleka.

(2) Ukubekwa kwengxenye

Izisetshenziswa: Khetha bese Ubeka Umshini.

Izinyathelo:

Layisha izingxenye ze-SMD kumphakeli womshini we-SMD.

Umshini we-SMD ucosha izingxenye ngombhobho futhi uzibeke ngokunembile endaweni eshiwo ye-PCB ngokohlelo.

Hlola ukunemba kokubeka ukuze uqinisekise ukuthi akukho offset, izingxenye ezingalungile noma izingxenye ezingekho.

Amaphuzu abalulekile:

I-polarity kanye nesiqondiso sezingxenye kufanele kube okulungile.

Umbhobho womshini we-SMD udinga ukugcinwa njalo ukuze ugweme ukulimala kwezingxenye.

(3) I-Reflow soldering

Izisetshenziswa: Isithando somlilo sokugeleza kabusha.

Izinyathelo:

Thumela i-PCB ekhweziwe esithandweni sokushisa sokugeleza kabusha.

Ngemuva kwezigaba ezine zokushisa, ukushisa okuqhubekayo, ukugeleza kabusha nokupholisa, i-solder paste iyancibilika futhi kwakhiwa ukuhlanganiswa okuthembekile kwe-solder.

Hlola ikhwalithi yokunamathisela ukuze uqinisekise ukuthi azikho iziphambeko ezinjengamajoyinti abandayo e-solder, amabhuloho noma amatshe amathuna.

Amaphuzu abalulekile:

Ijika lokushisa le-reflow soldering lidinga ukuthuthukiswa ngokuya nezici ze-solder paste kanye nezingxenye.

Linganisa izinga lokushisa lomlilo njalo ukuze uqinisekise ikhwalithi yokushisela ezinzile.

(4) Ukuhlolwa kwe-AOI (ukuhlola okuzenzakalelayo)

Izisetshenziswa: ithuluzi lokuhlola okuzenzakalelayo (AOI).

Izinyathelo:

Skena ngokubona i-PCB edayisiwe ukuze uthole ikhwalithi yamalunga e-solder nokunemba kokukhweza kwengxenye.

Rekhoda futhi uhlaziye amaphutha kanye nempendulo kunqubo yangaphambilini ukuze ulungiswe.

Amaphuzu abalulekile:

Uhlelo lwe-AOI ludinga ukuthuthukiswa ngokuya ngedizayini ye-PCB.

Linganisa okokusebenza njalo ukuze uqinisekise ukunemba kokutholwa.

2. Inqubo ye-DIP (dual in-line package).

Inqubo ye-DIP isetshenziswa kakhulu ukufaka izingxenye ze- through-hole (THT) futhi ngokuvamile isetshenziswa ngokuhambisana nenqubo ye-SMT.

(1) Ukufakwa

Izisetshenziswa: umshini wokufaka owenziwe ngesandla noma othomathikhi.

Izinyathelo:

Faka ingxenye yembobo endaweni ethile ye-PCB.

Hlola ukunemba nokuzinza kokufakwa kwengxenye.

Amaphuzu abalulekile:

Izikhonkwane zengxenye zidinga ukusikwa zibe ubude obufanele.

Qinisekisa ukuthi i-polarity yengxenye ilungile.

(2) I-wave soldering

Izisetshenziswa: isithando somlilo esishisayo.

Izinyathelo:

Beka i-plug-in PCB esithandweni sokushisa samagagasi.

Solder ingxenye yezikhonkwane kumaphedi e-PCB ngokusebenzisa i-wave soldering.

Hlola ikhwalithi yokusoda ukuze uqiniseke ukuthi awekho amajoyinti abandayo e-solder, amabhuloho noma amajoyinti avuzayo e-solder.

Amaphuzu abalulekile:

Izinga lokushisa nesivinini se-wave soldering idinga ukuthuthukiswa ngokuya nezici ze-PCB nezingxenye.

Hlanza i-solder okugeza njalo ukuze uvimbele ukungcola ukuthi kuthinte ikhwalithi yokunamathisela.

(3) Ukufakwa ngesandla ngesandla

Lungisa i-PCB mathupha ngemva kokuhlanganisa amaza ukuze ulungise iziphambeko (njengamajoyinti abandayo e-solder namabhuloho).

Sebenzisa i-soldering iron noma isibhamu somoya oshisayo ukuze uhlanganise indawo.

3. Ukutholwa kwe-AI (ukutholwa kobuhlakani bokwenziwa)

Ukutholwa kwe-AI kusetshenziselwa ukuthuthukisa ukusebenza kahle nokunemba kokutholwa kwekhwalithi.

(1) Ukutholwa okubonakalayo kwe-AI

Izisetshenziswa: Isistimu yokubona okubonakalayo ye-AI.

Izinyathelo:

Thatha izithombe ezinencazelo ephezulu ye-PCB.

Hlaziya isithombe usebenzisa ama-algorithms e-AI ukuze uhlonze amaphutha e-solder, ingxenye ye-offset nezinye izinkinga.

Khiqiza umbiko wokuhlola futhi uwubuyisele ohlelweni lokukhiqiza.

Amaphuzu abalulekile:

Imodeli ye-AI idinga ukuqeqeshwa futhi ithuthukiswe ngokusekelwe kudatha yangempela yokukhiqiza.

Buyekeza i-algorithm ye-AI njalo ukuze uthuthukise ukunemba kokutholwa.

(2) Ukuhlola okusebenzayo

Izisetshenziswa: Izinto zokuhlola ezizenzakalelayo (ATE).

Izinyathelo:

Yenza ukuhlolwa kokusebenza kukagesi ku-PCB ukuze uqinisekise imisebenzi evamile.

Rekhoda imiphumela yokuhlolwa futhi uhlaziye izimbangela zemikhiqizo enesici.

Amaphuzu abalulekile:

Inqubo yokuhlola idinga ukuklanywa ngokwezimpawu zomkhiqizo.

Linganisa imishini yokuhlola njalo ukuze uqinisekise ukunemba kokuhlolwa.

4. Inqubo ye-ASSY

I-ASSY inqubo yokuhlanganisa i-PCB nezinye izingxenye zibe umkhiqizo ophelele.

(1) Ukuhlanganisa imishini

Izinyathelo:

Faka i-PCB endlini noma kubakaki.

Xhuma ezinye izingxenye ezifana nezintambo, izinkinobho, nezikrini zokubonisa.

Amaphuzu abalulekile:

Qinisekisa ukunemba kokuhlanganisa ukuze ugweme ukulimala ku-PCB noma ezinye izingxenye.

Sebenzisa amathuluzi e-anti-static ukuvimbela ukulimala okumile.

(2) Ukushiswa kwesoftware

Izinyathelo:

Shisa i-firmware noma isofthiwe kumemori ye-PCB.

Hlola imiphumela evuthayo ukuze uqinisekise ukuthi isofthiwe isebenza ngokujwayelekile.

Amaphuzu abalulekile:

Uhlelo oluvuthayo kufanele lufane nenguqulo yehadiwe.

Qinisekisa ukuthi indawo eshisayo izinzile ukuze ugweme ukuphazamiseka.

(3) Ukuhlolwa komshini wonke

Izinyathelo:

Yenza izivivinyo ezisebenzayo emikhiqizweni ehlanganisiwe.

Hlola ukubukeka, ukusebenza nokuthembeka.

Amaphuzu abalulekile:

Izinto zokuhlola kufanele zihlanganise yonke imisebenzi.

Rekhoda idatha yokuhlola futhi ukhiqize imibiko yekhwalithi.

(4) Ukupakisha nokuthunyelwa

Izinyathelo:

Ukupakishwa kwe-Anti-static kwemikhiqizo efanelekayo.

Lebula, pakisha futhi ulungiselele ukuthunyelwa.

Amaphuzu abalulekile:

Ukupakisha kufanele kuhlangabezane nezimfuneko zokuhamba nezokugcina.

Rekhoda ulwazi lokuthumela ukuze ukwazi ukulandeleka kalula.

5. Amaphuzu abalulekile

Ukulawulwa kwemvelo:

Vimbela ugesi ongaguquki futhi usebenzise amathuluzi namathuluzi e-anti-static.

Ukulungiswa kwezisetshenziswa:

Njalo gcina futhi ulinganise imishini efana namaphrinta, imishini yokubeka, ama-ovens agelezayo, ama-wave soldering ovens, njll.

Ukuthuthukisa inqubo:

Lungiselela amapharamitha enqubo ngokuya ngezimo zangempela zokukhiqiza.

Ikhwalithi yokulawula:

Inqubo ngayinye kufanele ihlolwe ikhwalithi eqinile ukuze kuqinisekiswe isivuno.